The Silverware Manufacturing Process: From Raw Materials to Finished Product

You see a finished fork, but don't know the complex journey it took. This lack of knowledge makes it hard to judge quality and supplier capability, creating uncertainty.

Silverware manufacturing is a multi-step process. It starts with cutting and stamping a steel sheet into a rough shape. Then, it goes through rolling, trimming, and embossing, followed by multiple rounds of polishing, cleaning, and finally, packaging.

When I first walked Jacky through our factory, he was amazed. He saw how a simple, raw coil of steel was transformed, step by step, into the elegant silverware sets his brand is known for. He told me, "Linc, seeing the process in person is a game-changer. I now understand why precision at every station is so important." It gave him a new appreciation for the details. Let's walk through that same journey together so you can see exactly how your product is made.

What Are the Core Steps in Making a Piece of Silverware?

You want to ensure product quality, but the factory process is a black box. You worry about missed steps that could lead to defects in your final order.

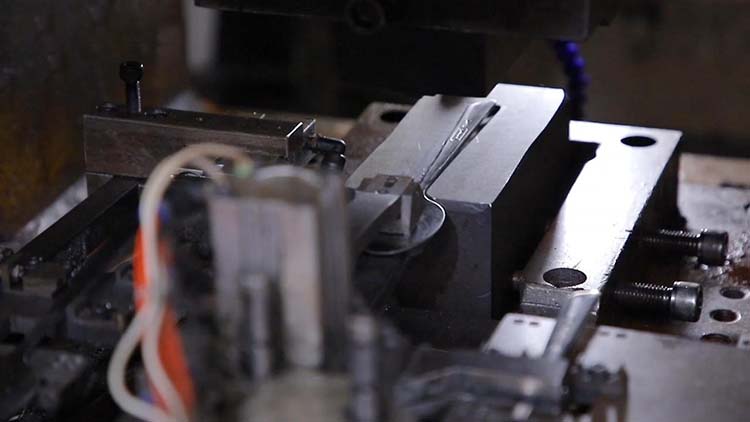

The process begins with cutting large steel coils into smaller sheets (cutting). These sheets are then stamped into basic flatware shapes (blanking). These rough shapes are rolled for thickness (rolling) and trimmed for a clean outline (trimming).

Everything starts with a huge, heavy coil of stainless steel. The first four steps are all about turning that raw material into a perfectly formed "blank," which is the flat, unfinished version of your fork or spoon. This initial shaping is purely mechanical and foundational for everything that follows. If we get these steps wrong, no amount of polishing can fix it. Each step has a precise function that contributes to the final strength and form of the piece. For example, the rolling process is far more sophisticated than just flattening metal; it's about redistributing it. We make the neck of the fork thicker for strength and the handle thinner for balance. This is where engineering meets mass production.

| Step | Action | Purpose |

|---|---|---|

| 1. Cutting | The large steel coil is unrolled and cut into strips. | To create manageable sheets of the correct width for the specific flatware model. |

| 2. Blanking | A high-pressure press stamps out the basic silhouette. | To create the rough outline of the fork or spoon from the steel sheet. |

| 3. Rolling | The blank is passed through rollers to vary its thickness. | To give the piece correct balance, strength, and an elegant feel. |

| 4. Trimming | A second press cuts away any excess metal. | To create a smooth, clean edge for the blank, preparing it for shaping. |

How is the Final Shape and Pattern Created?

You have a specific design in mind, with unique patterns and curves. You worry the factory can't replicate your vision with precision, leading to a generic-looking product.

The fine details are created through embossing, where patterns are stamped onto the handle. After that, die-cutting or pressing shapes the final curves and bowl of the spoon. Multiple, specific polishing steps then create the final lustrous finish.

This is where the silverware truly gets its personality. The flat, trimmed blank is now ready to become three-dimensional. The first part of this transformation is giving it a pattern. Using a custom-made mold with your design, a powerful press strikes the handle with immense force, a process called embossing. This creates the crisp lines and textures that define your product's look. Immediately after, another press gives the piece its final shape. For a spoon, this is when the flat oval becomes a functional bowl. For a fork, this shapes the gentle curve of the handle. Quality here is all about the tooling and calibration. A worn mold or incorrect pressure will result in a soft, undefined pattern—a flaw we never accept. After shaping, the real "finishing" begins with multiple stages of polishing to bring out the steel's natural beauty and create the desired look.

The Polishing Journey

- Rough Polish (Grinding): We start with a coarse

grinding wheel1 to remove any major imperfections and smooth the trimmed edges. - Medium Polish: We then switch to a

felt wheelwith a finer abrasive compound to buff out the grinding marks. - Fine Polish (Mirror Finish): Finally, a soft

cloth wheelis used for the last buffing stage, which brings the steel to a brilliant, mirror-like shine. For curved areas, we use specializedcurved polishing2 techniques to ensure every surface is flawless.

Why Does Every Single Step Matter for Quality?

You receive samples that look great, but you're not sure if the mass-produced order will hold up. Small, unseen issues could lead to rust or breakage later.

Every stage builds on the last. A poor trim requires excessive, harsh grinding that can weaken the steel. Incomplete cleaning before packaging can leave residues that cause rust during shipping. Attention to detail at every step is a non-negotiable part of quality control.

A beautiful finish can hide underlying problems. That’s why our quality control isn’t just a final check; it's embedded in every single step. A small error at the beginning can cascade into a major defect at the end. After the extensive polishing process, the final two steps are arguably the most critical for ensuring the product reaches your customer in perfect condition: cleaning and packaging.

The Crucial Final Steps

- Cleaning: The silverware carries oils and microscopic metal dust from the polishing process. If not removed, these contaminants can trap moisture and cause spotting or even rust. We use a multi-stage ultrasonic cleaning process with special solutions to ensure every piece is surgically clean before it is dried and inspected one last time.

- Packaging: Packaging is more than just branding; it's protection. For Jacky’s high-end line, we might use individual tissue wraps inside a

gift box. For a high-volume restaurant order, a simpleOPP bagfor each piece is enough to prevent scratching during shipment. We offer everything fromtie cardsandPVC boxesto luxurywooden cases, and we help you choose the option that best protects your investment.

This end-to-end control is how we guarantee that the 100,000th piece is as perfect as the first.

Conclusion

From a raw steel coil to a perfectly polished fork, each step in the manufacturing process is critical. Meticulous control ensures the final product meets the highest quality standards.