How Do You Choose the Right Stainless Steel Flatware Manufacturer for Bulk Orders?

Choosing the wrong flatware manufacturer can be a disaster. You risk poor quality, missed deadlines, and damaged brand reputation, turning a promising venture into a costly mistake.

To choose the right manufacturer, you must verify their material expertise, production capacity, and quality control systems. Also, assess their customization capabilities, delivery reliability, compliance certifications, and transparent pricing.

Finding a reliable partner for bulk orders is the most critical step for any flatware brand. I’ve seen firsthand what happens when this goes wrong. But I've also seen how a strong partnership can build a brand. We recently worked with a client from Romania who needed to develop a completely new flatware design. They were understandably cautious. We guided them through our entire process: creating the initial molds, providing samples, modifying them based on their feedback, running a small trial production, and conducting a rigorous pre-shipment inspection. The result? Every single piece met their high standards, the order was delivered on time, and they were thrilled with the consistent craftsmanship. This is the level of partnership you should expect. Let's break down exactly what to look for in a manufacturer.

How Can You Verify a Manufacturer's Material Expertise and Quality Control?

Are you worried about receiving products made from subpar materials? Inferior stainless steel can rust, bend, and fail to meet food safety standards, leading to customer complaints and potential legal issues.

Demand material certificates like mill test reports for food-grade stainless steel (304, 430). A reliable manufacturer will have robust quality control systems like ISO 9001, in-line inspections, and final pre-shipment checks.

The foundation of great flatware is the material. Your first question should always be about the type of stainless steel they use. Ask for documentation to prove it's genuine food-grade steel. But verification doesn't stop there. A trustworthy factory should have a structured quality control (QC) process. At XR Cutlery, we control every step of production in-house, from cutting the raw steel sheets to the final packaging. This gives us complete oversight. Look for a manufacturer who performs inspections at multiple stages of the production line, not just at the end. This prevents small issues from becoming big problems. Ask them about their defect traceability. Can they identify which production batch an issue came from? This level of detail shows a serious commitment to quality.

Does the Factory Have the Production Capacity and Customization Capability You Need?

Will your chosen factory be able to handle your order volume as your brand grows? And can they create the unique finishes and branding details that make your product stand out?

Assess their monthly output and experience with large-scale orders. A capable factory should offer extensive customization options, including custom engraving, PVD coatings, and unique designs, and provide samples for approval before mass production.

Production capacity is about more than just numbers. It's about maintaining quality at scale. A good manufacturer should be transparent about their monthly output (we produce over 60 million pieces annually) and be able to provide case studies of how they've handled large orders. Equally important is their ability to bring your vision to life. Customization is what separates a commodity product from a branded one. Can they do precise laser engraving for your logo? Do they have experience with PVD coatings for gold or black finishes? Our Romanian client needed a very specific engraved pattern. We produced multiple samples to ensure the depth and clarity were perfect before moving forward. A great partner works with you to get these details right. Always confirm their sampling process and be wary of any factory that is hesitant to provide pre-production samples.

How Do You Evaluate a Supplier's Reliability and Overall Partnership Potential?

Is the manufacturer you're considering a true partner, or just a transactional supplier? A supplier who misses deadlines, has hidden costs, or offers poor support can cripple your business operations.

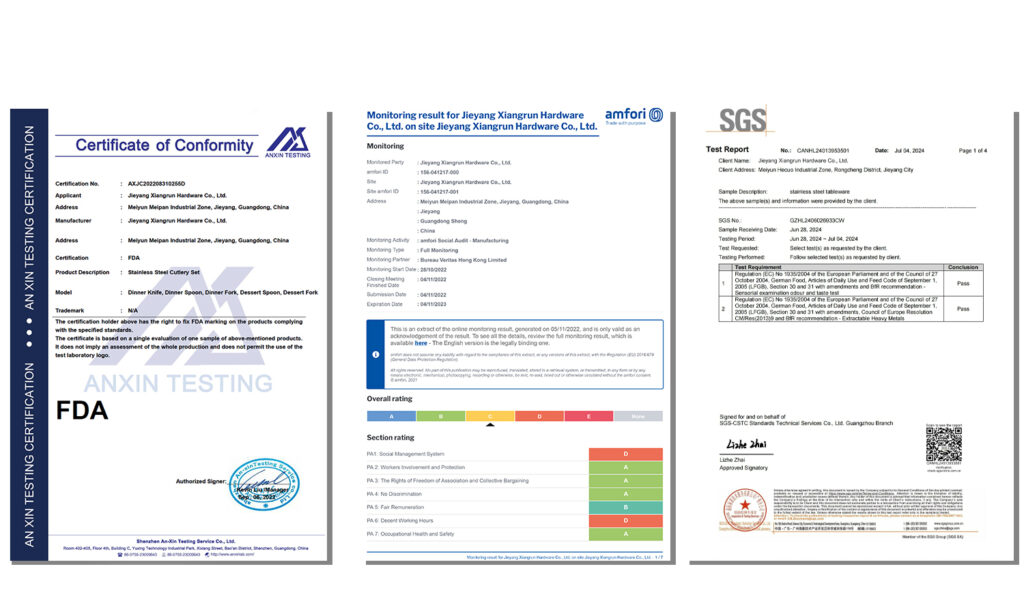

Evaluate reliability by confirming lead times, checking their logistics support, and asking for customer references. A true partner offers transparent pricing, comprehensive after-sales support, and holds necessary compliance certifications like FDA and LFGB.

A successful B2B relationship is built on trust and reliability. Before committing to a large order, you need to vet your potential partner thoroughly. Start with the basics: What are their standard lead times for stock and custom orders? How do they handle unexpected delays? Do they have established relationships with reliable freight forwarders? Next, look at their certifications. Compliance with international standards like FDA1 or LFGB is non-negotiable for products sold in the US or EU. Ask for references from other B2B buyers in your region. A confident manufacturer will be happy to provide them. Finally, ensure their pricing is completely transparent. The quote should break down every cost, from the unit price to tooling and shipping, so there are no surprises later. This transparency is the hallmark of a supplier who is invested in a long-term partnership, not just a single order.

How Can You Confidently Vet a Manufacturer Before Placing a Bulk Order?

How do you move from a promising conversation to a confident decision? Placing a large order without proper vetting is a huge risk, but traveling for a factory visit isn't always possible.

Vet a manufacturer by ordering samples to test quality firsthand. Review their company history and client feedback. And if you can't visit in person, consider hiring a third-party auditing service to inspect the factory on your behalf.

Vetting is the final, crucial step. The single most important action you can take is to order samples. Hold the product in your hands. Test its weight, balance, and finish. Check for polishing consistency and sharp edges. Run it through a dishwasher. The sample is a direct reflection of their mass-production quality. While you evaluate the samples, dig into the company's history. How many years have they been in business? Do they specialize in flatware? At XR Cutlery, our 20+ years of experience and our 8,000-square-meter facility speak to our stability and expertise. If a factory visit is feasible, do it. Seeing the production lines and meeting the team is invaluable. If not, a third-party audit2 is a great investment. They can provide an unbiased report on the factory's conditions, equipment, and QC processes, giving you the confidence you need to move forward with your bulk order.

If you're looking for a stainless steel flatware manufacturer3, our team at XR Cutlery is ready to help. Contact us, and we'll get back to you within 24 hours.

Conclusion

Choosing the right manufacturer is about finding a partner who excels in quality, capacity, and reliability. By thoroughly vetting their expertise and processes, you can build a relationship that ensures your brand's success.

-

Understanding FDA regulations is crucial for ensuring product safety and compliance in B2B transactions, protecting your business and customers. ↩

-

This link will provide insights into how third-party audits can enhance your confidence in a supplier's quality control. ↩

-

Discover top manufacturers to ensure quality and durability in your flatware choices. ↩