What Is 18/10 Stainless Steel and Why Does It Matter for Your Cutlery?

Confused by numbers like "18/10" on cutlery specs? You need quality flatware, but the technical jargon is unclear, risking a poor choice for your brand's standards.

"18/10" stainless steel means the alloy contains 18% chromium for rust resistance and 10% nickel for a brilliant shine and added durability. This specific composition makes it the premier choice for high-quality, beautiful, and long-lasting flatware.

Understanding these numbers is critical, especially when building a premium brand. I remember working with a client from Poland who was launching a new luxury flatware line. They wanted to compete with major brands, so the quality had to be perfect. They chose 18/10 stainless steel for its superior properties. We used our advanced polishing techniques to give it the flawless, smooth finish they needed. The result? Their new brand was a huge hit. This success started with choosing the right material. Let’s break down what makes 18/10 the gold standard.

What Does "18/10" Mean in Stainless Steel Cutlery?

Seeing "18/10" on a spec sheet can be confusing. You know it’s a sign of quality but may not know exactly why. This lack of clarity can be frustrating when sourcing products.

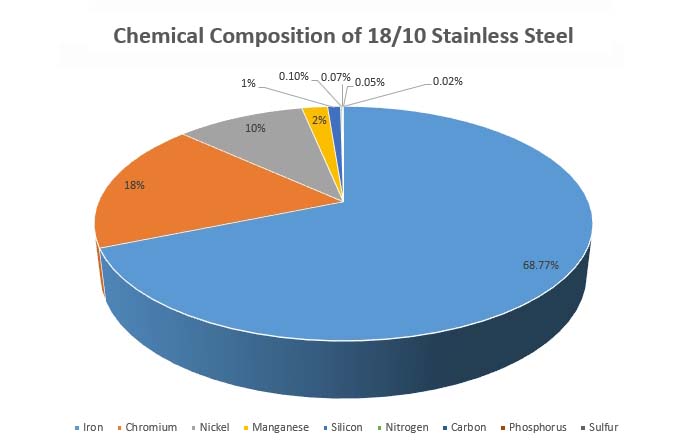

The "18" stands for approximately 18% chromium content, and the "10" signifies approximately 10% nickel content. The remaining balance is primarily iron. These percentages are the key to its superior quality.

When we talk about 18/10 stainless steel, we're describing its two most important alloying elements after iron. Each one plays a distinct and vital role in the final product's performance and appearance. Think of it as a recipe for high-performance metal.

The Core Components

- Chromium1 (18%): The Protector. This is the element that makes stainless steel "stainless." Chromium reacts with oxygen in the air to form a thin, invisible, and durable layer on the steel's surface. This passive layer protects the iron from rusting and corrosion.

- Nickel2 (10%): The Finisher. Nickel is a premium ingredient. It significantly boosts corrosion resistance, especially against acidic foods and detergents. More importantly for a luxury product, it provides a beautiful, bright, silver-like shine and a warm feel.

- Iron & Trace Elements: The Foundation. The rest of the alloy is mostly iron, providing the core structure and strength. Small amounts of carbon and manganese are also added to improve hardness and durability, particularly for knife blades.

How Do Chromium and Nickel Improve the Durability of 18/10 Stainless Steel?

You need cutlery that lasts. But how can you be sure it won't rust, stain, or bend after heavy commercial use? Choosing the wrong material leads to frequent, costly replacements.

Chromium forms a self-healing protective layer that stops rust before it starts. Nickel enhances this protection and adds toughness, making the flatware resilient to bending and everyday wear and tear.

The durability of 18/10 stainless steel isn't an accident; it's engineered. The synergy between chromium and nickel creates a material that is tough enough for the most demanding environments, like a busy restaurant. The chromium provides the primary defense. If the surface gets scratched, the chromium instantly reacts with oxygen to "heal" the protective layer, preventing rust from taking hold. The high nickel content adds another layer of defense. It makes the steel more stable and less reactive, which is why 18/10 flatware holds up so well against acidic substances like lemon juice or tomato sauce. Nickel also contributes to the material's ductility and toughness, meaning it can withstand being dropped or bent without deforming easily. This combination ensures that the flatware not only looks good but also maintains its structural integrity for years.

How Does the Composition of 18/10 Stainless Steel Affect Its Appearance and Finish?

Your brand's image depends on a premium look. You want a brilliant shine that communicates quality and doesn't fade. Dull, cheap-looking flatware can quickly damage your reputation.

The 10% nickel content is the main reason for the bright, silver-like luster of 18/10 steel. It creates a rich, warm tone and a highly polishable surface that resists dulling over time.

While chromium is the workhorse for durability, nickel is the artist that provides the beauty. The high nickel content gives 18/10 stainless steel its signature warm, brilliant shine that closely mimics the appearance of real silver. This is why it's the preferred choice for fine dining and luxury brands. The material's inherent luster means it can be polished to an incredible mirror finish that catches the light beautifully. This premium appearance is not temporary. The same properties that prevent corrosion also help prevent the surface from dulling or tarnishing, even after thousands of cycles in a commercial dishwasher. This was key for my Polish client; the exceptional shine we achieved was only possible because we started with a high-nickel 18/10 base. It provides a perfect canvas for creating a truly stunning product that holds its value and appearance.

How Does 18/10 Stainless Steel Compare to 18/8 and 18/0 Flatware?

You see 18/10, 18/8, and 18/0 options. They all look like stainless steel, but their prices vary. How do you choose the right one for your needs and budget?

The main difference is the nickel content. 18/10 has the most nickel, offering the best shine and rust resistance. 18/0 has no nickel, making it less resistant to corrosion but more affordable.

Understanding the difference between these grades is essential for making a smart purchasing decision. As a buyer like Jacky knows, the right choice depends on the application and budget. The chromium content is similar across all three, providing a good base level of rust protection. The nickel content is the real differentiator.

| Grade | Composition (Cr/Ni) | Key Properties & Use Case | Magnetism |

|---|---|---|---|

| 18/10 | ~18% Cr, ~10% Ni | Best quality. Superior shine, feel, and rust resistance. The standard for luxury flatware, fine dining, and high-end brands. | Non-Magnetic |

| 18/8 | ~18% Cr, ~8% Ni | Good quality. Very good rust resistance and shine. A solid choice for everyday quality household and good restaurant flatware. | Non-Magnetic |

| 18/0 | ~18% Cr, 0% Ni | Economy grade. Basic rust resistance, but more prone to staining and pitting over time. Lacks the luster of nickel grades. Often used in casual eateries or cafeterias. | Magnetic |

For high-end applications, 18/10 is the clear winner. For budget-conscious projects where a high-shine finish is less critical, 18/0 might be sufficient. 18/8 serves as a great middle-ground, offering excellent performance for most situations.

Conclusion

The "18/10" label signifies a superior blend of 18% chromium and 10% nickel, ensuring top-tier durability, rust resistance, and a brilliant, lasting shine for your cutlery collection.