How Does Flatware Thickness Really Affect Your Wholesale Order?

Choosing flatware by the "thicker is better" rule? This costly mistake can lead to unbalanced products, high costs, and slow-moving inventory for your wholesale business.

Flatware thickness is critical, but it's not the only factor. The real key is the balance between thickness, weight distribution, and design, which together determine durability, user feel, and overall cost.

As a factory owner, one of the biggest misconceptions I see from wholesale buyers is that thickness equals quality. They'll pick up a sample, feel its heft, and assume it's a premium product. But I've seen countless cases where "looks thick" actually means "feels clumsy." The reality is, the right thickness is a careful calculation. It's about finding the sweet spot that provides durability without sacrificing user comfort or destroying your budget. For a wholesale or distribution business, getting this balance right is the difference between a product that sells consistently for years and one that ends up as a clearance item. Let's break down what really matters.

Why Is 'Thicker is Better' a Costly Myth in Wholesale?

Are you paying a premium for extra-thick flatware? This strategy often backfires when customers complain that the pieces are clumsy, heavy, and uncomfortable to use in real-world dining situations.

The "thicker is better" myth ignores weight distribution and ergonomic design. A well-balanced, moderately thick piece of flatware feels far more premium and is more functional than a thick but poorly balanced one.

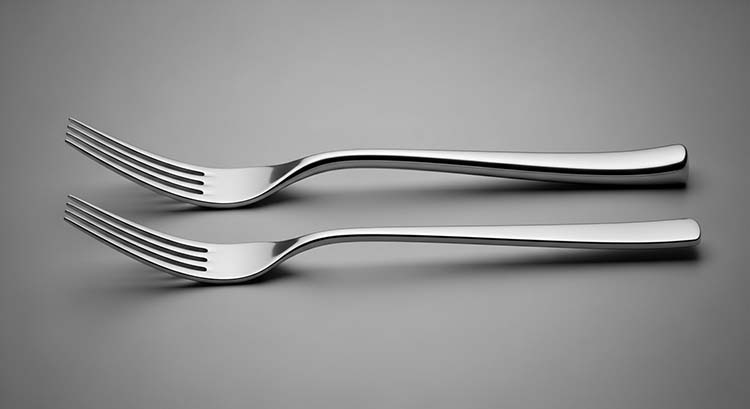

From a manufacturing perspective, the feel of a fork or spoon comes from a combination of three things: thickness, weight distribution, and the ergonomics of its curves and handle. Simply adding thickness without considering the other two is a recipe for a bad product. I've handled many pieces of flatware that looked impressive but were "head-heavy," meaning the functional end was too weighty, making it press uncomfortably into the user's hand. A truly premium piece of flatware feels balanced, like a good quality tool. This is achieved through thoughtful design, not just by using more steel. For a wholesale buyer, focusing only on thickness means you could be paying more for an inferior product experience. The goal should be to find a design that feels right in the hand, and that is often achieved in the medium-thickness range.

How Does a Millimeter of Thickness Impact Your Bottom Line?

Do you know how much a tiny change in thickness affects your total order cost? Underestimating this impact can lead to budget overruns and make your product uncompetitive in the market.

Even a 0.2-0.3mm increase in thickness can significantly raise the total raw material cost for a full container load. For a wholesaler, this isn't a one-time cost; it's a permanent increase in your reordering costs.

This is where the factory perspective is crucial. Let's talk numbers. When we quote a bulk order, the cost of raw stainless steel1 is a primary driver of the final price. If you increase the thickness of a fork by just 0.3mm, the weight of that single piece might only go up by a few grams. It seems insignificant. But when you multiply that by an order of 200,000 pieces for a full container, you are suddenly paying for hundreds of extra kilograms of stainless steel. This directly translates to a higher unit cost. For a distributor planning to carry a product line for 3-5 years, this small specification detail locks you into a higher cost structure for every future reorder. That's why at XR Cutlery, we work closely with our custom-order clients to be extremely precise about thickness, finding the optimal point that ensures durability without inflating the cost unnecessarily.

Should Your Flatware Thickness Change for Different Markets?

Are you trying to sell the same heavy, premium flatware in every market? This one-size-fits-all approach ignores crucial differences in customer expectations and price sensitivity, limiting your sales potential.

Yes, absolutely. European and North American markets often prefer a mid-to-heavy feel for durability. Price-sensitive markets prioritize appearance and price over thickness. E-commerce channels must also factor in shipping weight.

Understanding your end customer is key to choosing the right thickness. Your product specifications should adapt to your sales channels.

| Market/Channel | Typical Preference | Key Consideration |

|---|---|---|

| Europe / North America | 3.0mm - 5.0mm | Perceived durability and a sturdy feel are valued. Buyers are often willing to pay more for a product that feels substantial. |

| Price-Sensitive Markets | 2.0mm - 3.0mm | Visual appeal and a low price point are the primary drivers. A slightly thinner but well-polished product is often preferred. |

| E-commerce (D2C) | 2.5mm - 4.0mm | Weight is a critical factor as it directly impacts shipping costs. Finding the lightest possible option that still feels high-quality is the goal. |

| Hospitality (Hotels/Restaurants) | 3.5mm - 5.0mm+ | Extreme durability for constant use and industrial dishwashing is non-negotiable. Thickness directly relates to bending resistance. |

A smart wholesale strategy involves creating a tiered offering. You might have a robust, thicker line for your premium restaurant clients and a sleeker, more cost-effective line for your high-volume distribution or online channels.

How Can You Guarantee Consistency Between Samples and Bulk Orders?

Have you ever approved a perfect sample, only to receive a bulk order that "feels lighter"? This common and frustrating issue creates disputes and can damage your trust with a supplier.

The solution is to lock in specifications with numbers. Your contract should specify not just thickness (mm), but also a precise weight range (e.g., 45g ± 2g) for each item. This removes all ambiguity.

This is one of the most common sources of conflict in wholesale orders, and it's completely avoidable. "Feel" is subjective, but grams and millimeters are not. When you approve a pre-production sample, that sample should become the "gold standard," and its technical specifications must be documented. A professional factory2 will have no problem committing to these standards. The standard practice should be:

- Approve the Sample: You physically approve the sample for its design, balance, and feel.

- Measure and Document: The factory then provides you with the exact technical specifications of that approved sample, including its thickness at key points and its precise weight.

- Define Tolerances: You both agree on an acceptable tolerance for the mass production run (e.g., ±2 grams and ±0.1mm). This accounts for minor variations in manufacturing.

- Add to Contract: These exact specifications and tolerances are written into your purchase order or supply agreement.

This simple process transforms a subjective approval into an objective, measurable quality standard, protecting both you and the manufacturer.

Conclusion

The right flatware thickness is not about being the thickest; it's about finding the perfect balance of design, durability, and cost for your specific market, and locking in those specifications.