What’s the difference between OEM and ODM in cutlery manufacturing?

You need to source a new line of cutlery for your brand, but the factory terms are confusing. You hear OEM and ODM, but you're unsure which path is right for your project, risking delays and a product that doesn't match your vision.

OEM (Original Equipment Manufacturer) is when a factory builds your unique, custom design. ODM (Original Design Manufacturer) is when you select and re-brand one of the factory's existing, pre-made designs. OEM is about creation; ODM is about customization.

This is one of the first and most important conversations I have with any new client. A seasoned professional like Jacky, a buyer for a major US brand, knows this distinction by heart. The choice between OEM and ODM isn't just about manufacturing; it's a strategic business decision that impacts your budget, timeline, and brand identity. One path gives you total creative control, while the other offers speed and efficiency. Understanding the difference clearly is the first step toward a successful partnership and a product that meets your exact goals.

What is OEM in cutlery manufacturing?

You have a unique vision for a cutlery line that will stand out in the market. You worry a factory won't understand your design or have the technical skill to execute it precisely.

OEM means the factory acts as your dedicated production partner. You provide the detailed blueprints and specifications for your exclusive design, and we use our machinery and expertise to bring your specific product to life, and for you only.

When a top-tier brand comes to me, they are almost always looking for an OEM partnership. They aren't just buying cutlery; they are creating a signature element of their brand identity. In this relationship, you are the architect. You provide the detailed drawings, the exact weight, the material grade, the finish, and the packaging design. You own the intellectual property. My factory becomes your hands.

Our job is to take your vision and make it a physical reality. We first analyze your design to ensure it can be manufactured efficiently. Then, we begin the most critical part of the process: creating the high-precision steel molds. This is a significant upfront investment, but it's what allows us to produce your unique design flawlessly, thousands of times over. The entire process, from prototype to final quality check, is tailored to your specific standards. The result isn't just a product; it's a proprietary asset that belongs entirely to your brand and cannot be sold to anyone else. It's the path to true market differentiation.

What is ODM in cutlery manufacturing?

You want to launch a new cutlery line quickly to meet market demand. Designing a new product from scratch seems too slow, expensive, and full of risk.

ODM means you select a market-tested design from our factory's catalog. We then customize this product with your logo, unique finish, or branded packaging. It's the fastest and most cost-effective way to get a quality product to market.

ODM is a very popular and intelligent choice for many businesses, especially those who prioritize speed-to-market and lower initial investment. Think of it as choosing from a menu of excellent, pre-approved options. My factory has already invested in the research, design, and tooling for a wide range of cutlery patterns. We know they work, we know they are popular, and we have the production process completely optimized.

The process is straightforward. You browse our catalog and select a design that fits your brand's aesthetic. From there, the collaboration begins. You decide on the branding elements. Do you want your logo laser-etched1 onto the handle? Do you want a specific PVD2 color coating, like matte black or gold? Do you need a custom-designed gift box? We handle all of that for you. Because the expensive and time-consuming mold-making step is already done, the lead times are dramatically shorter and the upfront costs are much lower. It’s a powerful way to build out your product offering with proven designs.

What are the key stages in OEM cutlery production?

You've decided on an OEM project, but the manufacturing process seems like a complex black box. You're worried about missing a critical step, leading to costly mistakes and serious delays.

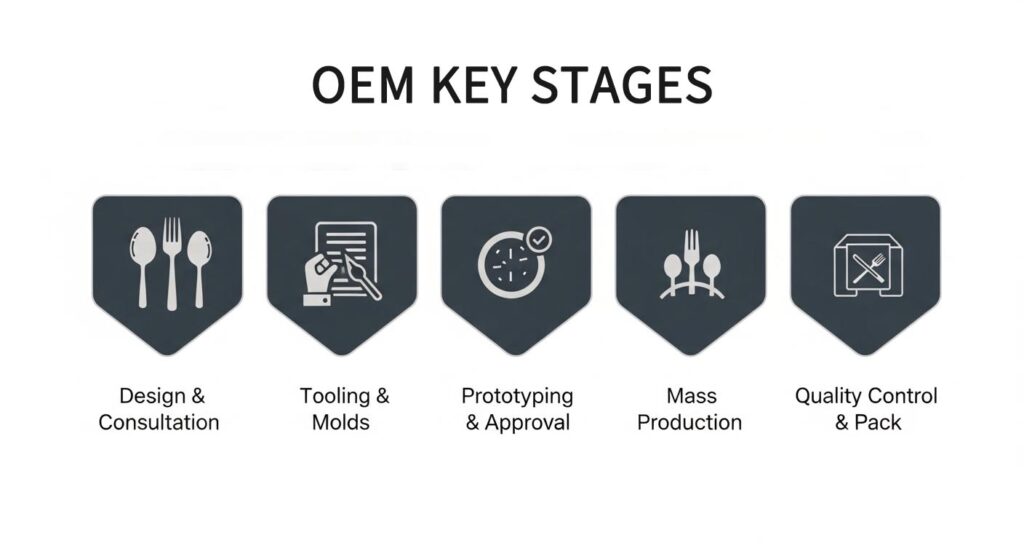

The key OEM stages are design consultation, tooling and mold creation, sample approval, mass production, and final quality control. Each stage is a checkpoint that requires your sign-off, ensuring the final product perfectly matches your vision.

I guide every OEM client through a structured, five-stage process. This transparency ensures there are no surprises and that you are in control at every critical milestone. It's a true partnership, and clear communication is essential.

| Stage | What Happens | Client's Role | Factory's Role |

|---|---|---|---|

| 1. Design & Consultation | We review your design ideas and technical drawings. | Provide detailed 2D/3D files, specify materials, finish, weight. | Analyze for manufacturability, suggest refinements. |

| 2. Tooling & Molds | We create the high-precision steel molds for your unique design. | Approve the final technical drawings before mold creation. | Manufacture the molds; this can take 4-6 weeks. |

| 3. Prototyping & Approval | We produce the first physical samples for you to test. | Rigorously inspect and test the sample for weight, feel, and quality. | Produce samples and make revisions if necessary. |

| 4. Mass Production | With sample approval, we begin the full production run. | Give the final "green light" for production. | Manage forging/stamping, polishing, and finishing. |

| 5. Quality Control & Pack | We inspect every piece based on agreed standards and pack it. | Provide AQL standards and packaging artwork. | Conduct inspections and package the goods for shipment. |

Each step logically follows the last, and your approval gates the entire process. This structured approach is how professional buyers like Jacky manage multi-million dollar orders with confidence. It transforms a complex process into a manageable series of clear-cut decisions.

How to verify a manufacturer’s OEM/ODM capability?

You've found a potential factory online, but their website makes big promises. You need to know if they truly have the experience to deliver, or if you're risking your investment on empty claims.

Verify a manufacturer by asking for case studies, requesting certifications like ISO 9001, conducting a factory audit, and checking their engineering team's experience. For ODM, review their catalog's depth; for OEM, inspect their mold-making workshop.

Talk is cheap. Before I partner with any major brand, they do their homework on me, and I expect it. You must look past the website and verify a factory's true capabilities. Here are the practical things I recommend you do, whether you're working with me or another supplier.

For an OEM partnership, you are vetting their technical skill:

- Ask About Their Engineers: Do they have an in-house engineering team? Can they work with your 3D files?

- Inquire About Molds: Do they make their own molds in-house? A factory with its own tooling workshop has far more control and expertise. This is a huge sign of a serious OEM player.

- Request Technical Samples: Ask to see non-confidential samples of other complex OEM products they have made. This shows you their real-world capabilities without revealing other clients' designs.

For an ODM partnership, you are vetting their design library and efficiency:

- Review Their Catalog: Is it extensive, with modern and appealing designs? A thin, outdated catalog is a red flag.

- Ask About Customization: How flexible are they? Can they offer different finishes (PVD, tumble, etc.), handle materials, or complex logo applications?

- Check Lead Times: For their standard items, they should be able to give you a clear and confident timeline for production.

For both, always ask for quality certifications (like ISO 90013 for process management) and social compliance audits (like BSCI4). The ultimate verification is a factory audit, either in person or through a trusted third-party service.

Conclusion

Choosing OEM means creating a unique product from scratch, while ODM means branding a proven design. Understanding this key difference is essential for aligning your manufacturing strategy with your business goals.

-

Explore this link to understand how laser-etching enhances brand visibility and product appeal. ↩

-

Explore this link to understand PVD coating's benefits and applications in enhancing product aesthetics. ↩

-

Understanding ISO 9001 can enhance your knowledge of quality management systems and their benefits for businesses. ↩

-

Exploring BSCI will provide insights into social compliance standards and their impact on ethical sourcing. ↩