Is 304 stainless steel good for knife making?

You hear 304 steel is a premium material, perfect for flatware. But choosing it for a knife would be a huge mistake, leading to blades that can't cut.

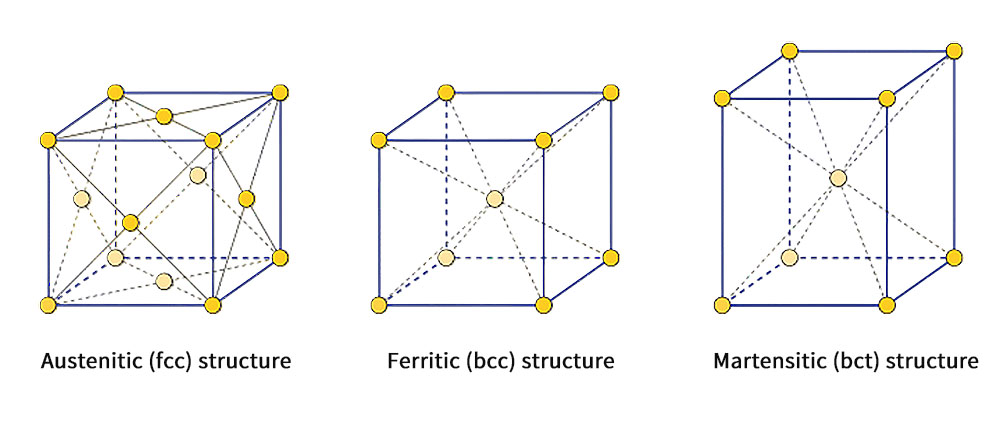

No, 304 stainless steel is not good for making knife blades. It is an austenitic steel that is too soft to be heat-treated and cannot hold a sharp edge. The industry standard for quality table knives is a martensitic steel like Grade 420, which is specifically designed for hardness and cutting performance.

This is one of the most critical distinctions in my business. When a client like Jacky, an experienced procurement director, places an order for a new flatware set, we have two separate material discussions. One is for the forks and spoons, and the other is for the knives. The function of the utensil dictates the type of steel we must use. Using a premium material like 304 (or 18/10) for a fork is perfect. Using it for a knife blade would lead to a product that fails from day one. Understanding why is essential for anyone buying or selling quality cutlery.

What is the best stainless steel for knife making?

Choosing a knife steel is confusing with so many grades available. The wrong choice results in a dull, useless blade that damages your brand's reputation for quality and performance.

For table knives and most general-purpose kitchen knives, Grade 420 stainless steel is the best and most common choice. It provides an ideal balance of high hardness for edge retention, good corrosion resistance for food use, stability, and cost-effectiveness.

In my factory, the production line for knives is completely separate from the one for forks and spoons, and it all starts with the steel. You simply cannot make a good knife from the same steel as a spoon. A knife's primary job is to cut, which requires a material that can be made very hard. This is where 420 steel excels. It belongs to a family of "martensitic" stainless steels. This means it has a specific crystal structure with higher carbon content that can be transformed through heat treatment. We heat the forged blades to a very high temperature and then cool them rapidly. This process locks the steel's structure into a very hard state, allowing it to be sharpened to a durable edge. While it has less chromium than 304 steel and is slightly less rust-resistant, its hardness is the most important feature for a blade, making it the perfect industry standard.

What is the difference between 304 and 420 stainless steel knives?

The numbers 304 and 420 might seem like minor details. But a knife made from 304 stainless steel would be a complete failure, resulting in a useless tool that can't cut.

The critical difference is hardness versus corrosion resistance. 420 is a hard, martensitic steel that can be heat-treated to hold a sharp cutting edge. 304 is a soft, austenitic steel that cannot be hardened. A 420 knife cuts effectively; a 304 knife would be useless for cutting.

I once had a new client who insisted on a "full 304" flatware set because they heard it was the best. I had to explain that while it's perfect for forks and spoons, a 304 knife would crush a tomato, not slice it. The difference lies in their fundamental structures.

- 420 Stainless Steel (Martensitic): This steel has more carbon and is designed for hardness. Its crystal structure allows it to be hardened by heat, making it ideal for blades. We call this "cutlery grade" steel.

- 304 Stainless Steel (Austenitic): This steel has high chromium and nickel content, making it excellent at resisting rust. Its structure is stable and cannot be hardened by heat. It is designed to be formed and shaped, not to hold an edge. It is perfect for items like pots, pans, forks, and spoons.

Here is a clear breakdown:

| Feature | 304 Stainless Steel | 420 Stainless Steel |

|---|---|---|

| Primary Use | Forks, Spoons, Pots, Tanks | Knives, Surgical Tools |

| Key Property | Corrosion Resistance, Formability | Hardness, Edge Retention |

| Hardens by Heat? | No | Yes |

| Magnetic? | No | Yes |

| Nickname | "18/8" or "Food Grade" Steel | "Cutlery Grade" Steel |

Is 420 stainless steel food grade?

You hear "Grade 420" and it might sound industrial, not like something safe for food. This doubt could make you hesitate on what is actually the ideal material for knives.

Yes, 420 stainless steel is absolutely food grade and perfectly safe for contact with food. It is one of the most widely used materials for cutting tools in the food industry, including dinner knives, steak knives, kitchen knives, and even surgical instruments.

The term "food grade1" simply means a material is safe for food contact and won't leach harmful chemicals or affect the food's flavor. Grade 420 easily meets this standard and is approved by safety authorities like the FDA for food applications. The reason it's so popular is that it solves a specific problem. You need a knife to be hard to cut well, but it also needs to resist rust from food acids and washing. 420 steel offers the perfect compromise. It can be made hard enough to slice a steak cleanly while still having enough chromium to resist corrosion in a normal dining environment. While it might not be as rust-proof as a 304 steel spoon, it doesn't need to be. Its main job is to cut effectively and safely, and for that, it is the undisputed champion in the world of affordable, high-performance table knives.

Will stainless 304 rust?

You invested in premium 304 (18/8 or 18/10) flatware, believing it was totally rust-proof. Now you see a small spot of rust, and you feel confused and let down.

Yes, even high-quality 304 stainless steel can rust under specific, harsh conditions. Although it is highly resistant to corrosion, prolonged exposure to salt, strong acids, or harsh dishwasher detergents can damage its protective surface layer and allow rust spots to form.

The name "stainless" is a bit misleading; a better name would be "stain-resistant." I always tell my clients that 304 steel's resistance comes from a microscopic, invisible layer of chromium oxide on its surface. This "passive layer" protects the steel underneath. If this layer is damaged, rust can occur. This is not a sign of a defective product but a result of environmental conditions. The most common reasons for rust on flatware are:

- Chlorides: Salt is the number one enemy. Leaving flatware to soak in salty water or not rinsing it after a salty meal can cause pitting and rust.

- Harsh Detergents2: Some dishwasher detergents contain high levels of chlorine (bleach), which is very aggressive and can break down the protective layer.

- Abrasives: Scrubbing with steel wool or other abrasive pads will scratch the surface and remove the passive layer, inviting rust.

- Leaving it Wet: Allowing flatware to sit in a puddle of water in the dishwasher or sink prevents the passive layer from reforming.

With simple care—rinsing after use and drying promptly—your 304 stainless steel will look perfect for a lifetime.

Conclusion

For knife making, 304 steel is too soft. Hard, food-grade 420 steel is the industry standard for blades. 304 remains the best choice for forks and spoons but requires care.